Coke oven gas, also known as coke oven gas. Refers to a preparation of several bituminous coking coal, after high temperature carbonization in a coke oven, a combustible gas and tar products in the output of the coke produced at the same time, a byproduct of coking industry. Coke oven gas is a mixture, the yield and composition vary depending on the quality coking coal and coking process conditions vary, generally produce dry coal per ton of coke oven gas 300 ~ 350m3 (standard state). The main components of hydrogen (55% to 60%) and methane (23% to 27%), also contains small amounts of carbon monoxide (5% ~ 8%), C2 or more unsaturated hydrocarbons (2% to 4%), carbon dioxide (1.5% to 3%), oxygen (0.3% to 0.8%)), nitrogen (3% to 7%). Wherein hydrogen, methane, carbon monoxide, C2 or more unsaturated hydrocarbon as combustible components, carbon dioxide, nitrogen, oxygen, nonflammable component.

Coke oven gas belongs to the calorific value gas, the heat value per standard cubic meter of 17 ~ 19MJ, high-temperature industrial furnaces used for fuel and city gas. Coke oven gas containing hydrogen gas high, after the separation for ammonia, methane and other components such as ethylene can be used as organic synthesis.

Coke oven gas is toxic and explosive gases, air explosion limit of 6% to 30%.

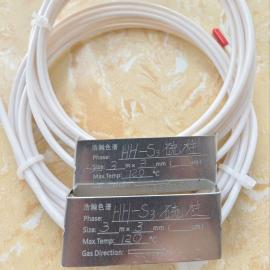

Tengzhou City Technology Co., Ltd. Xiangying analysis developed 5A + Porapak Q packed column Determination of the coke oven gas component, with satisfactory results.

焦炉气,又称焦炉煤气。是指用几种烟煤配制成炼焦用煤,在炼焦炉中经过高温干馏后,在产出焦炭和焦油产品的同时所产生的一种可燃性气体,是炼焦工业的副产品。焦炉气是混合物,其产率和组成因炼焦用煤质量和焦化过程条件不同而有所差别,一般每吨干煤可生产焦炉气300~350m3(标准状态)。其主要成分为氢气(55%~60%)和甲烷(23%~27%),另外还含有少量的一氧化碳(5%~8%)、C2以上不饱和烃(2%~4%)、二氧化碳(1.5%~3%)、氧气(0.3%~0.8%))、氮气(3%~7%)。其中氢气、甲烷、一氧化碳、C2以上不饱和烃为可燃组分,二氧化碳、氮气、氧气为不可燃组分。

焦炉气属于中热值气,其热值为每标准立方米17~19MJ,适合用做高温工业炉的燃料和城市煤气。焦炉气含氢气量高,分离后用于合成氨,其它成分如甲烷和乙烯可用做有机合成原料。

焦炉气为有毒和易爆性气体,空气中的爆炸极限为6%~30%。

浩瀚色谱(山东)应用技术开发有限公司研发出5A+Porapak Q填充柱,测定测定了焦炉煤气组分,结果满意。

扫一扫,手机浏览

扫一扫,手机浏览