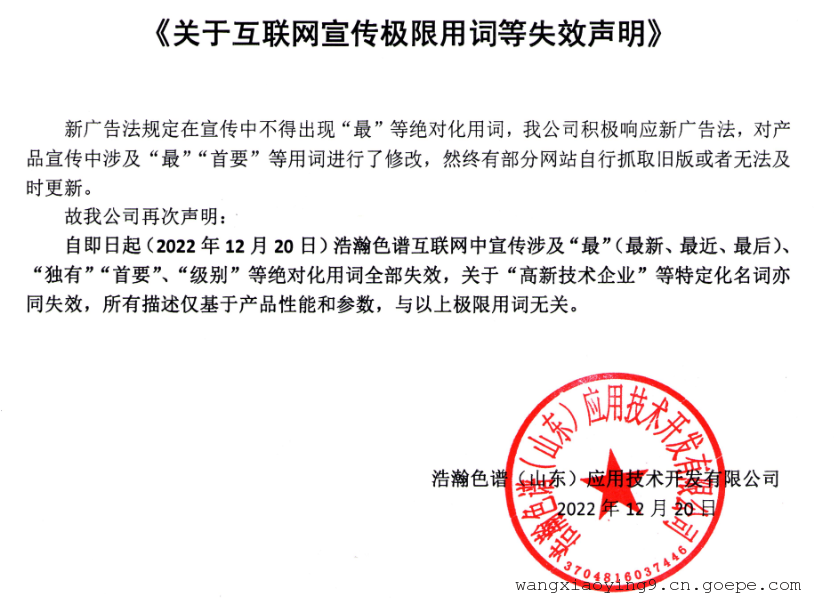

- УРЙњ1/8гЂДчЙшЭщЛЏВЛатИжЙм6m*1/8

ЯъЯИаХЯЂ

ЙмКёЃК0.5 mm жБОЖЃК3.17 mm ЦЗХЦЃКУРЙњ аЭКХЃК6m*1/8 РраЭЃККсЯђад БкКёЃК0.5 ЕШМЖЃК1 1/8гЂДчЙшЭщЛЏВЛатИжЙЃК1/4 1/16ЃКбѕЛЏбЧЕЊ гаЛњСзЃКгаЛњТШ БНЯЕЮяЃКЗжзгЩИ 3%Dexil-300/ChromosoЃКЛЗбѕввЭщ ВЛатИжЙмТЗОЙ§ЖЦФЄЖлЛЏЙЄвеММЪѕДІРэЙ§КѓЕФЬиЕуЃКЧхНрЁЂЖшадЧПЁЂФЭИЏЪДЁЃ

ВЛатИжЙмТЗЕФБэУцДІРэЃК

1.ЃКБэУцЖшадЛЏДІРэЃЌЪЪгУгкМЋадЛюЦУЛЏКЯЮяЕФЗжЮіЙ§ГЬЃЌppbМЖБ№ЕФгаЛњСђЛЏЮяЕФЗжЮіЁЃ

2.ЃКдкБэУцИВИЧвЛВуФЭИЏЪДЭПВуЃЌбгГЄД§ДІРэЮядкЫсадЛЗОГЯТЕФЪЙгУЪйУќЁЃШчбЮЫсЁЂЯѕЫсЛђКЃЫЎЛЗОГЯТЁЃ

3. ЃКО ЫЎНтШЅЛюММЪѕДІРэЕФВЛатИжЙмТЗЃЌгаЧПЕФПЙЫЎНтЬиадЃЌЪЪгУгкЙмТЗМАЩИАхЕФЧхЯДЃЌвВгУгкЖЅПеНјбљЯЕЭГЁЃ

4.ЃЌЪЪгУВЃСЇЁЂФјКЯН№ЁЂВЛатИжБэУцДІРэЃЌppb МЖЮШЖЈДЂДцЃЌСїЬхНщжЪДЋЪфКЭГЩЗжЗжЮіЁЃ

ЙцИёЃК1/16,1/8,1/4

ВњЕиЃКУРЙњ

гІгУЃКVOCS,ЃЌЗЧМзЭщзмЬўЃЌСђЛЏЮяЃЌАБЃЌЫсЃЌИЏЪДадЦјЬхЃЌБНЯЕЮя

The characteristics of stainless steel pipelines treated with coating passivation technology include cleanliness, strong inertness, and corrosion resistance.

Surface treatment of stainless steel pipelines:

1. Surface inerting treatment, suitable for the analysis process of polar active compounds and ppb level organic sulfide analysis.

2. Cover the surface with a corrosion-resistant coating to extend the service life of the treated material in acidic environments. In environments such as hydrochloric acid, nitric acid, or seawater.

3. Stainless steel pipelines treated with hydrolysis deactivation technology have strong anti hydrolysis properties, suitable for cleaning pipelines and sieve plates, and are also used in headspace injection systems.

4. Suitable for surface treatment of glass, nickel alloy, and stainless steel, stable storage at ppb level, fluid medium transmission, and composition analysis.

Specifications: 1/16, 1/8, 1/4

Origin: United States

Application: VOCS, non-methane total hydrocarbons, sulfides, ammonia, acids, corrosive gases, benzene series

Сє бд

-

ВњЦЗЫбЫї

-

ВњЦЗЗжРр

-

ЦјЯрЩЋЦзвЧЃЈ9ЃЉ

-

ЦјЯрЩЋЦзвЧгІгУЃЈ2981ЃЉ

- ЪЏЛЏвКЛЏЦјЖўМзУбЩЋЦзЗЈ

- ЪГгУжВЮягЭЦјЯрЩЋЦзМьВт

- ЕЭЬМжЌЗОАЗЦјЯрЩЋЦзЗЈ

- ЪГЦЗЃЈАзОЦЃЉЦјЯрЩЋЦзЗЈ

- ЪГЦЗвНвЉАќзАЦјЯрЩЋЦзЗЈ

- ЙЄвЕЛЏбЇЦЗВтЖЈЦјЯрЩЋЦзЗЈ

- ЩњЮявНвЉВтЖЈЦјЯрЩЋЦзЗЈ

- ПеЦјЃЈЮлШОЮяЃЉЦјЯрЩЋЦзЗЈ

- ЭПСЯВтЖЈЦјЯрЩЋЦзЗЈ

- УКЛЏЙЄЦјЯрЩЋЦзМьВт

- ЙЄвЕЃЈгРОУЃЉЮоЛњЦјЬхМьВт

- ЫЎжЪгаЛњЮяЦјЯрЩЋЦзВтЖЈ

- ХЉвЉЃЈВаСєЃЉЦјЯрЩЋЦзЗЈ

- Я№ЫмЙЄвЕЦјЯрЩЋЦзМьВт

- ЯуОЋЯуСЯЦјЯрЩЋЦзЗЈ

- гаЛњЙшЕФЦјЯрЩЋЦзЗЈ

-

ЦјЯрЩЋЦзМьВтЦїЃЈ8ЃЉ

-

вКЯрЩЋЦзвЧЃЈ47ЃЉ

-

ЖЅПеНјбљЦїЃЈ3ЃЉ

-

ЕЊЧтПеЗЂЩњЦїЃЈ6ЃЉ

-

ЩЋЦзжљЃЈ424ЃЉ

-

ЩЋЦзХфМўЃЈ101ЃЉ

-

вКЯрЩЋЦзвЧХфМўЃЈ6ЃЉ

-

ЪЕбщЪвГЃгУЩшБИ

-

ЫЎЗжВтЖЈвЧ

-

гагАЯьСІЕФПЭЛЇ

1.жаЙњЧиЩНКЫЕчеО2.ЮїАВПЦММДѓбЇ

3.ЮїЗяОЦГЇ

4.ФЯОЉЙЄвЕДѓбЇ

5.жаЙњЪЏгЭЬьШЛЦјЙЩЗнгаЯоЙЋЫО

6.жаЙњЗјЩфЗРЛЄбаОПЫљ

7.жаЙњЪЏгЭДѓбЇ

8.ЩНЖЋРэЙЄДѓбЇ

9.ФЯОЉЙЄвЕДѓбЇЛЏЙЄбЇдК

10.ЖЋФЯДѓбЇ

11.аьжнЪажЪСПММЪѕМрЖНОж

12.ЛнжнЪаЪЏгЭВњЦЗжЪМрОж

13.ЩНЖЋй№ПѓМЏЭХ

14.КгФЯаХбєЪІЗЖЛЏбЇЛЏЙЄбЇдК

15.СЩбєЪажЪСПММЪѕМрЖНОж

16.КгББИпБЎЕъЪаММЪѕМрЖНОж

17.ЩНЖЋЛЏЙЄжАвЕбЇдК

18.ЩНЖЋРэЙЄДѓбЇ

19.ЩђбєЛЏЙЄбаОПдК

20.МЊСжЪажЪСПММЪѕМрЖНОж

21.ГЄЧьгЭЬябгАВВЩгЭГЇ

22..ЪЄРћгЭЬя

23.БІМІжЪСПММЪѕМрЖНОж

24.бюСшжЪМрОж

25.ЛЊЖЋНЛЭЈДѓбЇ

26.ЬЋдЕчСІИпЕШзЈПЦбЇаЃ

27.ФЯОЉСжвЕДѓбЇ

28.ЩНЖЋХЉПЦдКжВЮяБЃЛЄбаОПЫљ

29.ЛДББЪІЗЖДѓбЇ

30.жЃжнДѓбЇ

31.быЦѓ--жаДЂСИМЏЭХЙЋЫО

32.ГіПк--УЩЙХЙњ

33.жаЙњЬњТЗзмЙЋЫО

34.ФЯЭЈДѓбЇ

35.ЩНЮїХЉвЕДѓбЇ

36.ЛЊЖЋРэЙЄДѓ

37.быЦѓ--жаЗФМЏЭХ

ЩЈвЛЩЈЃЌЪжЛњфЏРР

ЩЈвЛЩЈЃЌЪжЛњфЏРР