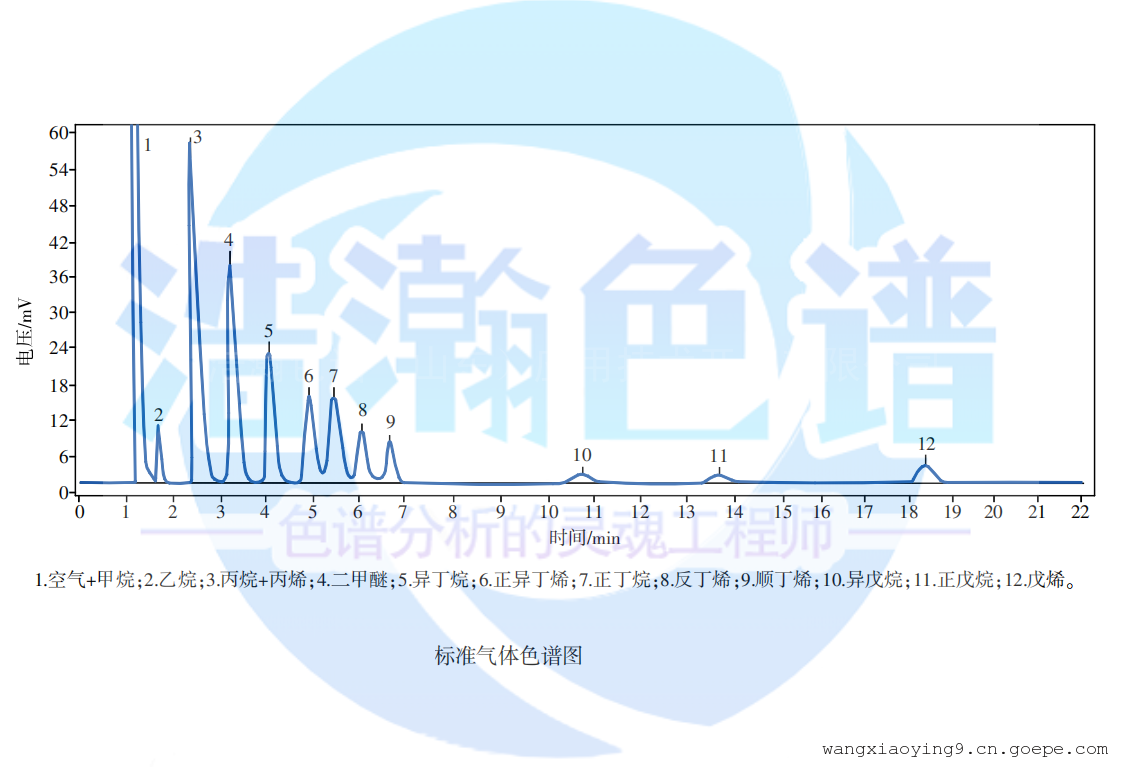

- haohan二甲醚分析专用毛细管柱30m*0.53mm

详细信息

品牌:haohan 型号:30m*0.53mm 加工定制:是 测量范围:ppm 测量对象:二甲醚 控温范围:200 ℃ 尺寸:30000 mm 重量:0.5 Kg 二甲醚:液化气 甲缩醛:乙缩醛 三苯:二甲苯 甲醛:甲醇 苯系物:消毒剂

Dimethyl ether production methods are one-step and two-step method. One-step method refers to the synthesis of dimethyl ether from the feed gas, the two-step synthesis of methanol from the synthesis gas, and then dehydration system of dimethyl ether.

In this case,

One-step production line of methyl ether

In this case,

The synthesis gas is fed into the synthesis reactor through the natural gas conversion or the coal gasification, and the two reaction processes and the conversion reaction of the methanol synthesis and the methanol dehydration are completed simultaneously in the reactor. The product is a mixture of methanol and dimethyl ether , The mixture was separated by the distillation device of dimethyl ether, unreacted methanol back to the synthesis reactor.

In this case,

One-step multi-use of dual-function catalyst, the catalyst is generally two types of catalysts from the physical mixture, one of which is the synthesis of methanol catalyst, such as Cu-Zn-Al (O) -based catalyst BASFS3-85 and ICI-512; One type is methanol dehydration catalyst, such as alumina, porous SiO2-Al2O3, Y type molecular sieve, ZSM-5 molecular sieve, mordenite and the like.

In this case,

Two-step method

In this case,

The method is carried out in two steps, namely, synthesis of methanol from the synthesis of methanol, methanol in the solid catalyst dehydration of dimethyl ether. The ZSM-5 zeolite containing γ-Al2O3 / SiO2 is used as a dehydration catalyst in the world. The reaction temperature was controlled at 280-340 ° C and the pressure was 0.5-0.8 MPa. The single-pass conversion of methanol is between 70-85% and the selectivity of dimethyl ether is more than 98%.

In this case,

Compared with the two-step method, the process is simple, the equipment is small, the investment is small and the operation cost is low, so the production cost of DME is reduced and the economic benefit is improved. Therefore, one-step synthesis of dimethyl ether is a hot spot at home and abroad. Developed a representative one-step process abroad: Denmark Topsφe process, the United States Air Products and Japan NKK process technology.

In this case,

Two-step synthesis of dimethyl ether is the main process of dimethyl ether production at home and abroad, the method to fine methanol as raw materials, dehydration reaction by-product less dimethyl ether purity of 99.9%, mature technology, equipment adaptability, Treatment is simple, can be directly built in the methanol production plant can also be built in other public facilities good non-methanol production plant. But the law to go through methanol synthesis, methanol distillation, methanol dehydration and dimethyl ether distillation process, a longer process, and thus a larger investment in equipment. However, most of the large-scale DME construction projects announced by foreign countries adopt the two-step process technology, which shows that the two-step method has strong comprehensive competitiveness.二甲醚的生产方法有一步法和二步法。一步法是指由原料气一次合成二甲醚,二步法是由合成气合成甲醇,然后再脱水制取二甲醚。

甲醚生产线一步法

该法是由天然气转化或煤气化生成合成气后,合成气进入合成反应器内,在反应器内同时完成甲醇合成与甲醇脱水两个反应过程和变换反应,产物为甲醇与二甲醚的混合物,混合物经蒸馏装置分离得二甲醚,未反应的甲醇返回合成反应器。

一步法多采用双功能催化剂,该催化剂一般由2类催化剂物理混合而成,其中一类为合成甲醇催化剂,如Cu-Zn-Al(O)基催化剂,BASFS3-85和ICI-512等;另一类为甲醇脱水催化剂,如氧化铝、多孔SiO2-Al2O3、Y型分子筛、ZSM-5分子筛、丝光沸石等。

二步法

该法是分两步进行的,即先由合成气合成甲醇,甲醇在固体催化剂下脱水制二甲醚。国内外多采用含γ-Al2O3/SiO2制成的ZSM-5分子筛作为脱水催化剂。反应温度控制在280~340℃,压力为0.5-0.8MPa。甲醇的单程转化率在70-85%之间,二甲醚的选择性大于98%。

一步法合成二甲醚没有甲醇合成的中间过程,与两步法相比,其工艺流程简单、设备少、投资小、操作费用低,从而使二甲醚生产成本得到降低,经济效益得到提高。因此,一步法合成二甲醚是国内外开发的热点。国外开发的有代表性的一步法工艺有:丹麦Topsφe工艺、美国Air Products工艺和日本NKK工艺。

二步法合成二甲醚是目前国内外二甲醚生产的主要工艺,该法以精甲醇为原料,脱水反应副产物少,二甲醚纯度达99.9%,工艺成熟,装置适应性广,后处理简单,可直接建在甲醇生产厂,也可建在其它公用设施好的非甲醇生产厂。但该法要经过甲醇合成、甲醇精馏、甲醇脱水和二甲醚精馏等工艺,流程较长,因而设备投资较大。但目前国外公布的大型二甲醚建设项目绝大多数采用两步法工艺技术,说明两步法有较强的综合竞争力。

规格:规格 DME专用柱

***高使用温度(°C) 适应范围

30m*0.53mm*40um 液化气站 液化石油气 工业二甲醚 -

供应商的其他相关信息

查看更多

-

产品搜索

有影响力的客户

1.中国秦山核电站2.西安科技大学

3.西凤酒厂

4.南京工业大学

5.中国石油天然气股份有限公司

6.中国辐射防护研究所

7.中国石油大学

8.山东理工大学

9.南京工业大学化工学院

10.东南大学

11.徐州市质量技术监督局

12.惠州市石油产品质监局

13.山东兖矿集团

14.河南信阳师范化学化工学院

15.辽阳市质量技术监督局

16.河北高碑店市技术监督局

17.山东化工职业学院

18.山东理工大学

19.沈阳化工研究院

20.吉林市质量技术监督局

21.长庆油田延安采油厂

22..胜利油田

23.宝鸡质量技术监督局

24.杨凌质监局

25.华东交通大学

26.太原电力高等专科学校

27.南京林业大学

28.山东农科院植物保护研究所

29.淮北师范大学

30.郑州大学

31.央企--中储粮集团公司

32.出口--蒙古国

33.中国铁路总公司

34.南通大学

35.山西农业大学

36.华东理工大

37.央企--中纺集团

扫一扫,手机浏览

扫一扫,手机浏览